Two years ago, I drew a flow chart to guide importers in case a final QC inspection was failed.

Two years ago, I drew a flow chart to guide importers in case a final QC inspection was failed.

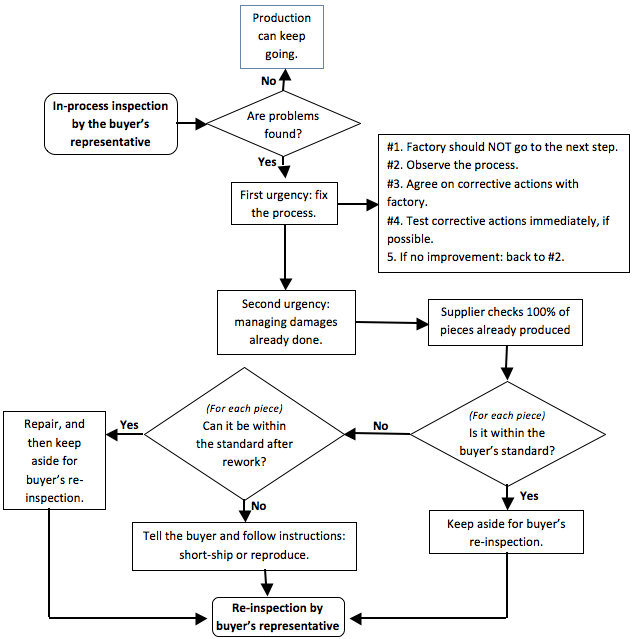

But the best is to detect problems during an in-process inspection (before the products are finished).

At this stage, if an issue is caught by an inspector, there are 2 objectives:

- To make sure the same problem won’t be present on the pieces that will go through that same process later;

- To make sure the pieces that already bear this problem are dealt with in the right way.

So I drew another flow chart, specifically for in-process inspections:

What do you think? Anything to add to this procedure?

HI Renaud!!!In my experience #3.Agree on corrective actions with factory could take some time(it depends hours or may be a whole day),while the production line still in process and making more faulty products.

That’s true. The client should force the factory to stop that process if no agreement is found fast.